What is the best cleaning power worth if the cleaning bath contains oil that re-contaminates the parts? By simply measuring the contamination level process, reliability can be increased as well as improving cost-effectiveness.

An increasing level of contamination caused by grease or oil left by machined parts in cleaning baths will cause a decrease in the cleaning power of the rinsing media and a high parts cleanliness cannot be guaranteed even if an optimal cleaning agent concentration is used.

In order to ensure high process reliability and efficiency, contamination must be regularly removed from the cleaning bath, such methods include for example settling tanks, coalescence separators, separators or membrane filters and evaporators. Their effectiveness and proper functioning can be maintained through a quick and easy inspection of bath contamination.

If the amount of contamination exceeds the filter capacity, an increased contamination level will be determined immediately. By controlling the contamination level directly after filtration can ensure the functioning and effectiveness of the filter.

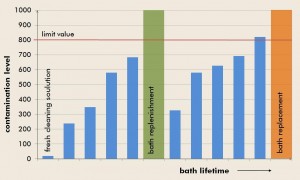

The image to the right shows the bath contamination of a bath lifetime over two weeks and clearly shows that the contamination level increases during the production. Monitoring bath care will lead to a reduction of bath contamination. By setting a certain limit value in the cleaning bath once this has been reached, a fresh cleaning bath solution should be prepared, thus improving the cost effectiveness of the cleaning bath process.

For flexible, at the process line monitoring of bath contamination, the ConSpector cleanliness test instrument can quickly measure the contamination of cleaning fluid quickly and easily making it possible to efficiently determine the optimum time for fresh prepared cleaning bath or bath care actions.

The mobile instrument offers the benefits of various measuring profiles for a different baths or liquids; optional calibration to fresh cleaning solution and an alarm can be set that will sound when limit values are exceeded.

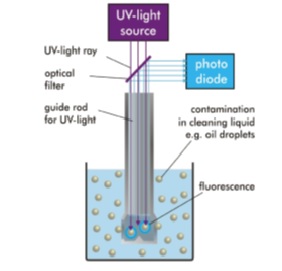

The ConSpector detects organic bath contamination such as oils and greases through their fluorescence which is excited by UV light of an LED in the sensor head.

The UV light or fluorescence light is lead into the liquid by a light guide rod in the sensor head. A photodiode in the sensor head measures the fluorescence intensity and a high bath contamination will give a high measurement value. The measured results can be interpreted as follows: the higher the measured value of fluorescence, the higher the specific bath contamination.

Measurements are made at the touch of one button and displayed in RFU (Relative Fluorescence Unit). The results can be stored in the instrument memory or with the ProcessLog software which enables management and graphical analysis of saved measuring data can be stored on the PC.

Typical Contamination Detection in Cleaning Baths using the ConSpector Application Examples:

- Cooling lubricants

- Rolling oil

- Grease

- Deep drawing oils

- Release agents

For information on how to monitor and control your cleaning bath contamination levels using the ConSpector, please contact our Sales Team at Dyne Testing Ltd via email or by telephoning 01543 411460.